|

|

Mineral Processing Equipment Laboratory Flotation Machine

| Mineral Processing Equipment Laboratory Flotation Machine 220V 120W |

|

| Flotation machine is applicable for separating non-ferrous metal, black metal, noble metal, non-metal mineral and raw materials of chemical industry. It can be used in geology, metallurgy, building materials, chemical and other industrial laboratories to float a small quantity of ore samples and also in education and many mine sites. It is one of the best choices for you to do the test about the mine recovery and synthesis on your begining stage before mass mining. |

Technical Parameters :

Voltage:220V 1PH

Power:

120 W 50/60hz

Model Volume :1.5L

Impeller Diameter:60mm

Impeller speed:0-2800

Scraper speed: 15-30rpm

Feed size:≤0.25

Heating power: 200W

Temperature adjustment range:50-95 degree centigrade.

Product size:17.1*12.4*32.7 inch

|

|

High efficiency work, the working motor is much quieter than other electric opportunities, to provide you with a more comfortable working environment. |

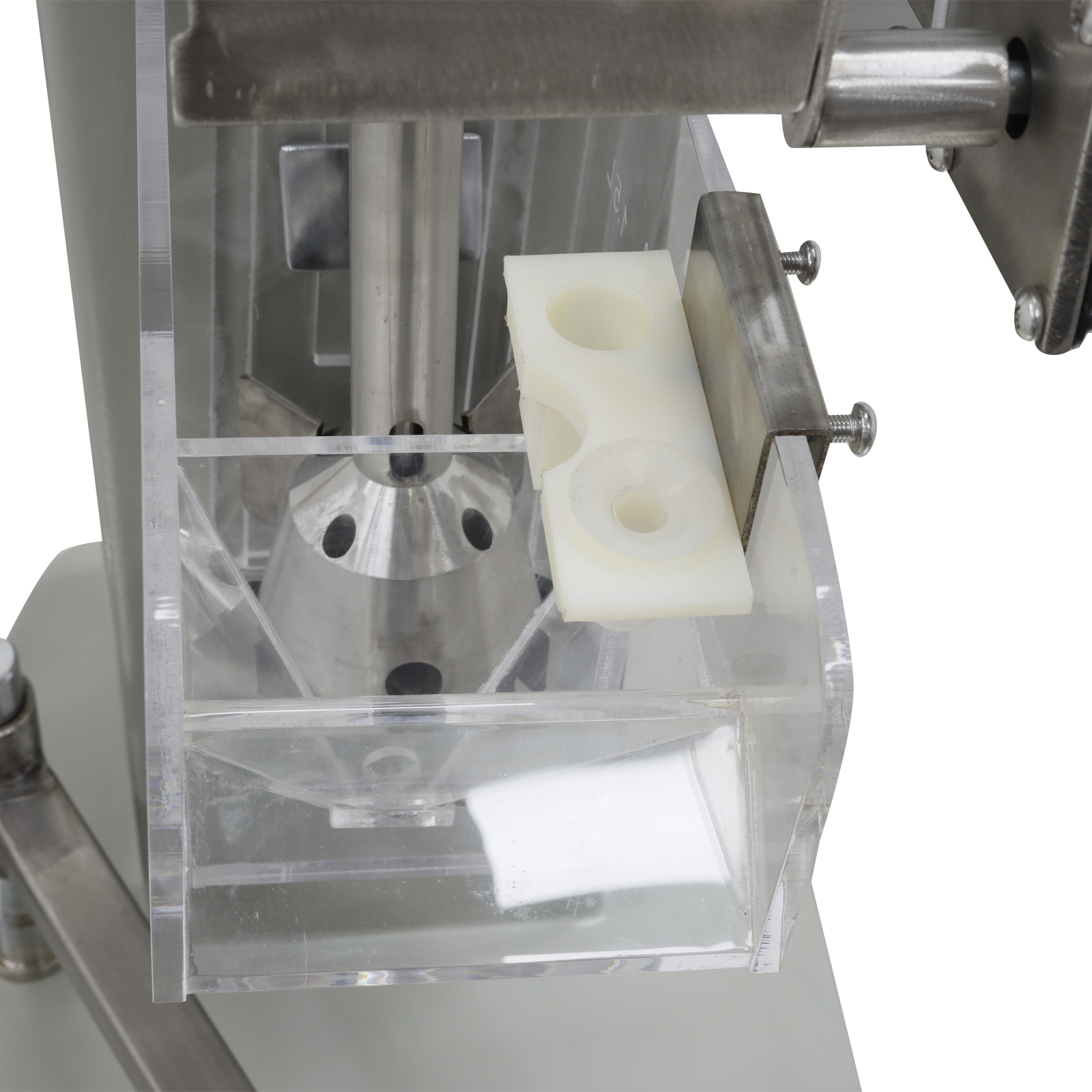

| 1.5L cell body |

|

|

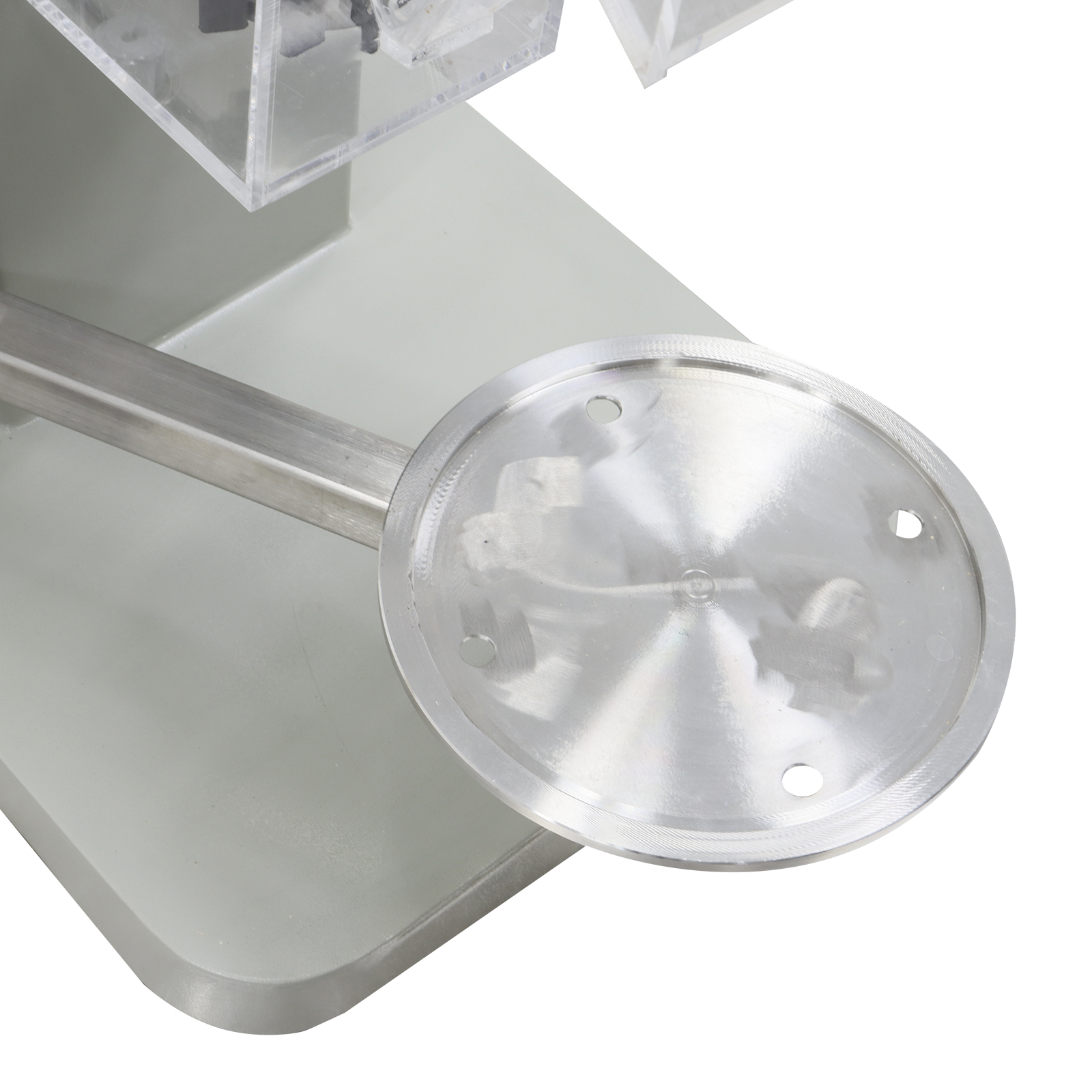

7" Tray,Position can be adjusted freely. |

Glass rotameter for gas/air flow meter with control valve.

20 Degree Celsius/101325Pa

Allow the gas to be measured ≤ 1MPa |

|

|

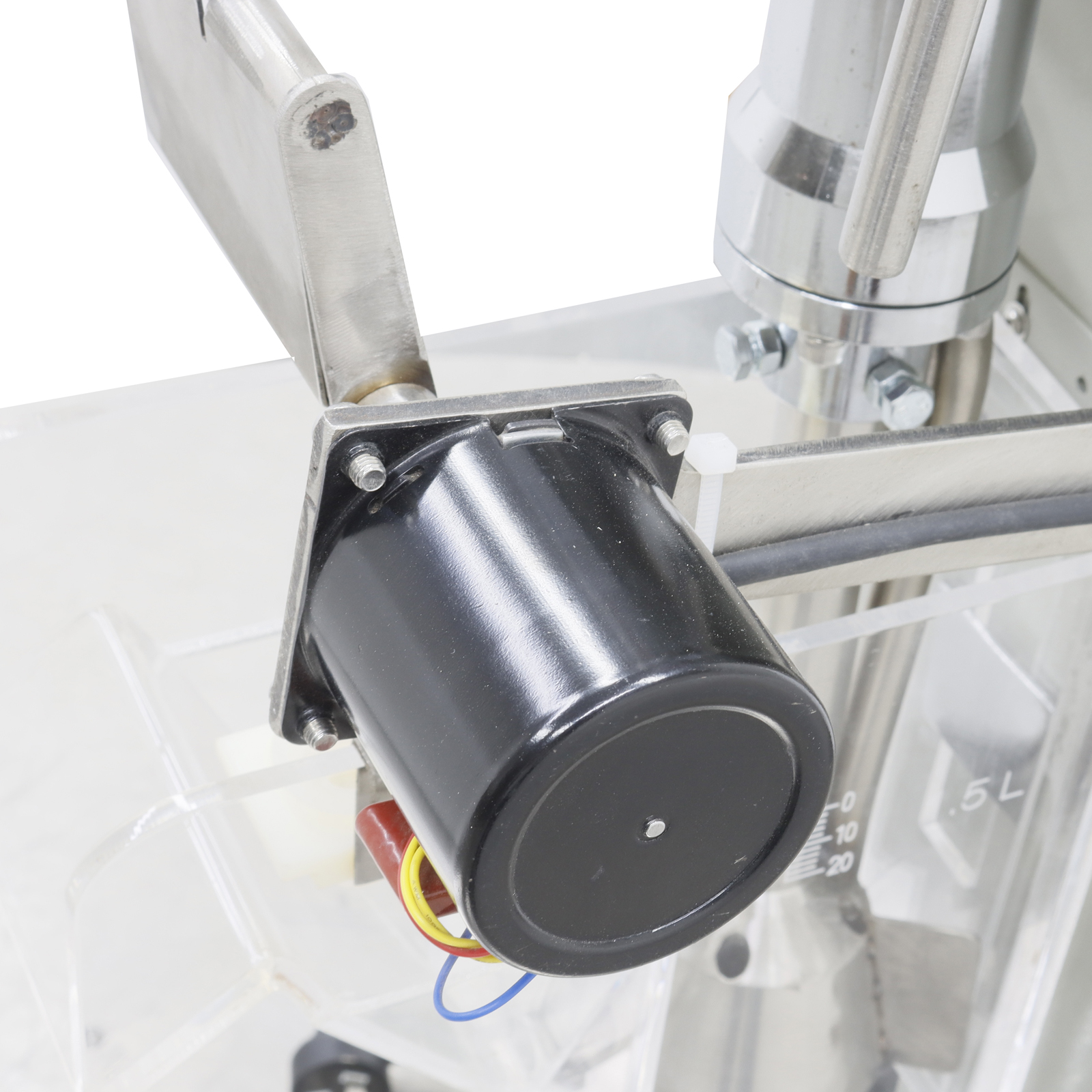

Scraper Motor |

Use:

1,Turn on the power supply;

2,Test starting: check the rotation direction of the spindle, it must be rotated clockwise, if not, the phase sequence of the power supply should be changed to make the motor rotate clockwise before it can start working;

3,The mineral sample and water are mixed into the tank, the motor is started, the main shaft rotates, the impeller in the tank begins to stir, and then the valve is opened to inflate, and the foam can be formed after the required agent is added;

4,Place the thermometer and the heating rod into the side-hung groove.

5,Turn on the scraper motor switch to make the scraper rotate, then the foam can be scraped out of the notch, the material box is placed on the workbench, and the required mineral species can be obtained after the scraped foam is treated.

6.Turn off the power after use. |

Maintenance:

1, Each time before starting work, check whether there is a foreign body blockage in the instrument groove, the Impeller and the belt are matched, and the screw linkage is normal.

2, Lubricating oil should be added to each rotating joint, and the lubricating oil at the bearing should be replaced every three months (melting point of grease ≥100℃).

3, The instrument should be wiped clean after each use.

4. When replacing the impeller and stator, first unscrew the impeller, then loosen the fastening screws connecting the stator to the lower body, and finally install the new impeller and stator.

5. When moving the flotation machine, the force application points should be on the machine body, not on any components, to avoid damage.

6. The operating temperature of the flotation cell is 15-50℃. |

|

Item# |

QTY |

| 134163 |

1 |

|

Item included:Mineral Processing Equipment Laboratory Flotation Machine 220V 120w*1

Item Number: 134163 |

| You can make order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in normal condition.

Handling Time: Shipping is usually made in 1-3 business days after payments cleared. Orders are processed from Monday-Friday; Not on the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty period has expired, you can still seek for service or technical support from us with low cost. |

|