|

|

|

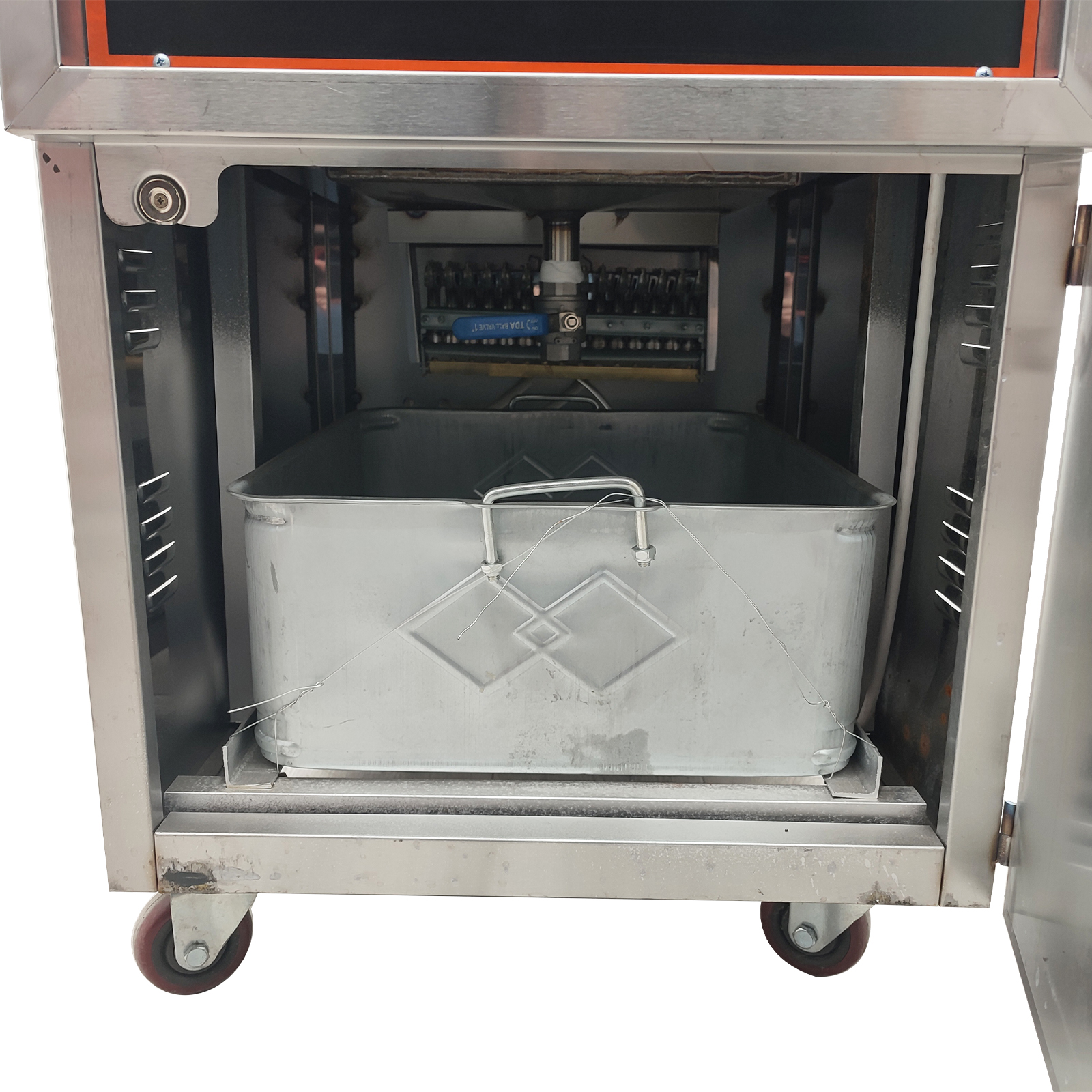

110V CNC high pressure fried chicken stove liquefied

petroleum gas

|

|

|

|

|

|

|

|

The gas

energy-saving fried chicken stove has the advantages of automatic

temperature control, automatic ignition, gas heating flameout

protection, fast heating, low gas consumption, stable performance and

reliable quality. It is suitable for hotels, canteens and individual

businesses.

|

|

|

Parameters

|

|

Rated

voltage

|

110V

|

Fryer

oil capacity

|

35KG

|

|

Rated

frequency

|

50Hz-60Hz

|

Productivity

|

25KG/h

|

|

Rated

input power

|

150W

|

Temperature control range

|

20℃~ 250℃

|

|

Gas

type

|

liquefied petroleum gas

|

Timing

range

|

0-99 minutes

|

|

Rated

air pressure

|

2.8Kpa

|

Dimensions

|

104*52*116cm (40.94x20.47x45.67 Inches)

|

|

Gas

consumption

|

1.0KG/h

|

Rated

working pressure

|

0.0833Mpa

|

|

|

Main Working

Principle

|

|

By means of the

automatic control of microcomputer programs and the combination with

electronic automatic temperature controller, the ignition and start-up

of the combustion system, temperature rise and heating, automatic

constant temperature, flameout protection alarm, and safety protection

of the stove body are achieved.

|

|

Product

Features

|

|

|

1. Using gas fire to generate heat, stable and efficient.

2. The capacity of the pot is about 45L. You can fry 6-8 ducks at a time.

3. Thickened aluminum cover, durable, no rust.

4. With sealing ring, good sealing effect, easy to clean.

5. Triple safety valve protection. Automatic exhaust valve, manual exhaust valve, safety valve. Effective and safe pressure relief. Combined with a kilo screw, very strong.

6. Intelligent digital temperature control. The buttons on the control panel are simple and easy to use for novices.

7. Complimentary frying basket, handle, gas low pressure valve.

8. The lower part of the pot body is allocated with an oil basin, which has large space and is more convenient for oil pouring.

|

|

Installation

Method

|

|

1. Place the

fried chicken stove steadily and check whether all components have been

damaged during transportation. If there are any problems, these problems

must be solved before use.

2. The

equipment cannot be placed near wooden walls, flammable materials cannot

be placed around the equipment, smoke exhaust and ventilation facilities

must be installed indoors, and fire extinguishers must be available

nearby to ensure safety. (The gas inlet connector is located on the

lower portion of the interior of the electrical box, and the electrical

box door needs to be opened in the installation process.)

3. Connect the

equipment to the LPG tanks with a gas hose

and the equipment gas inlet reliably, and fix both ends of the hose with

clamps. There should be no gas leakage in the gas transmission section,

and no sundries can be piled up around it. Only low-pressure valves are allowed, and the use

of high-pressure and medium pressure valves is prohibited.

4. The power

connection should be carried out by electrical professionals, and the

power supply voltage should be consistent with the rated voltage on the

label. The power cord must be connected to a power socket with a leakage

protector and overload protection device.

5. The machine

shell is equipped with a bolt for the grounding mark, and the user must

firmly connect the protective grounding wire that complies with safety

regulations.

|

|

Precautions

|

|

1. Do not touch

the exhaust outlet to avoid scalds in the frying process.

2. Only the

electrical professionals are allowed to open the electrical box.

3. Children are

strictly prohibited from approaching the device in the using process so

as to avoid scalds.

4. For safety

production, the machine must be connected to a safety grounding device,

otherwise it cannot be used.

5. Do not

directly contact the heat source around the gas source, and do not store

flammable materials to avoid accidents.

6. After

filling the fryer with oil, be sure to check whether the fasteners on

the fryer cover are secure in place before heating, and then tighten the

seal to prevent the injury caused by detachment in the using process.

7. Before the

fried food is taken out, the exhaust valve must be opened to release the

air. After the air in the fryer is completely discharged, the pressure

gauge pointer should return to the "0" position. After one minute, the

fryer cover can be opened.

8. It is

strictly prohibited to hit the handle, cover and fryer mouth with hard

objects to prevent accidents.

9. When the

cover does not work, it can be closed, but it must not be tightened so

as to prevent long-term compression and aging deformation of the sealing

ring.

10. Clean away

the impurities in the safety valve pipeline timely to prevent blockage.

The rated oil quantity should be maintained in the fryer, otherwise the

normal production will be affected.

11. When the

customer stops using the machine, the power supply must be cut off and

the angle valve of the gas source must be closed.

|

|

Warning:Only

low-pressure valves are allowed, and the use of high-pressure and medium

pressure valves is prohibited.

|

|

|

|

|

Item Number: 220529

|

|

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.

|

|